Reverse Osmosis

|

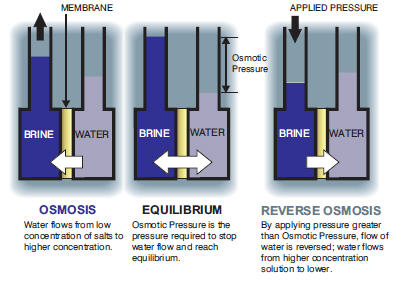

The Reverse Osmosis process uses a semi-permeable membrane to separate and remove dissolved solids, organics, pyrogens, submicron collodial matter, viruses, and bacteria from water. The process is called "Reverse" Osmosis since it requires pressure to force pure water across a membrane, leaving the impurities behind. Reverse Osmosis is capable of removing 95 - 99% of the total dissolved solids (TDS) and 99% of all bacteria, thus providing safe, pure water.

|

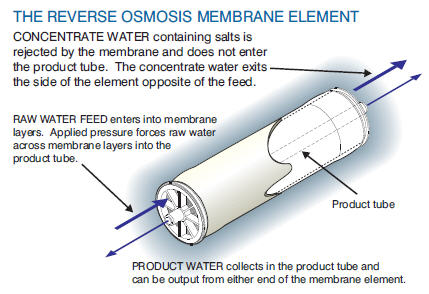

Crane Environmental uses spiral-wound Reverse Osmosis elements constructed from a thin-film composite membrane material. Raw water containing salts and impurities is fed into the membrane element, and the feed pressure supplied by the Reverse Osmosis system pump forces the water through the pores in the membrane for collection in the product tube in the center of the membrane element. Water containing impurities is passed out of the element along the surface of the membrane and does not enter the product tube. |

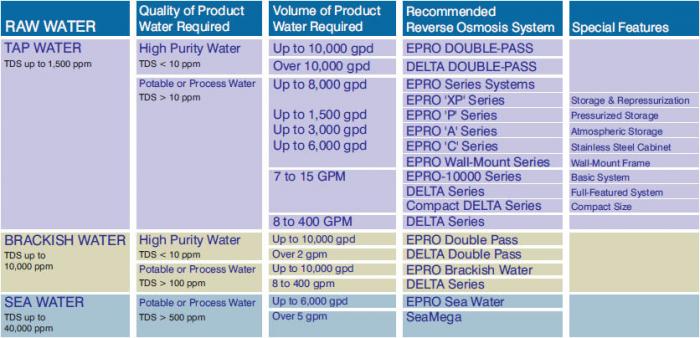

Selecting the Right Reverse Osmosis SystemCrane Environmental has the most complete line of Reverse Osmosis equipment in the industry. To select the right Reverse Osmosis system for your application, there are four primary considerations; the type of raw water, the quality of the product water required, the capacity of product water required, and any special features such as storage, repressurization, or mounting. Crane model numbers describe the amount of product water each system will produce; the EPRO model numbers indicate the gallons per day (GPD) of product, and the DELTA system model numbers indicate the number of gallons per minute (GPM) of product. |

|

|

|